Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: V425

Brand: Calstar

Brand: Calstar

Texture Of Material: 304 Stainless Steel

Storage Capacity: 225

Weight: 96kg

Dimension: 898X1132X1860 Mm

Packaging: Wooden box

Productivity: 500set

Transportation: Ocean

Place of Origin: Shenzhen, China

Supply Ability: 10 sets per day

Certificate: ISO14000,ISO9001,Ex,CE

Port: Shenzhen

Payment Type: L/C,T/T

Incoterm: FOB

Vacuum Pressure Reducing Device in San Francisco

Vacuum decompression recovery device, special auxiliary device, made for organic solvent recovery, large capacity, removeble and safe structure, pneumatic operation, is manufactured according to Chinese explosion-proof standards

The vacuum on the distillation machine can be required for higher boiling and easy to decompose, taste is big, the toxic organic solvent waste recycling such as CFCs, acetones, MEK (Methyl ethyl ketone / butanone), DMF, DMSO,MPK (Methyl n-Propyl Ketone), alcohols, etc.

Solvent Recovery and Recycling Waste Solvent Benefits:

Reduce virgin solvent purchases

Reduce solvent chemical waste and Reduce hazardous waste generator permit status

Lower storage costs

Obtain quicker return on investmenton capital equipment and safer yet more expensive engineered solvents

Solvent reclaimation and recovery systems can greatly reduce costs, hazardous waste disposal, solvent consumption while increasing process stability and operation.

Contact Calstar for more information and to test your parts!

V425 Vaccum Pump

It is suitable for assembling with Calstar Organic Solvent Recycling Machine 60L/90L/100L/125L/200L/225L/425L Solvent Recycling Machine to use.

Characteristic

●Explosion-proof electric equipment: in compliance with Chinese safety standards (CNEX) and European standards (ATEX), worry-free and safe for use;

●Fully stainless steel enclosure: greasy dirt can be gently wiped clean, dirty easy to clean, so that equipment is always kept clean and new;

●Operation is simple, convenient, easy and simple; no power supply, pneumatic operation, automatic feeding, safty for use;

●Large capacity, easy to store;

●Vacuum decompression recovery: condensation, vacuum, storage features and variety of functions in one machine; heating temperature is low, saving heating electricity; sealed recycling, reduces evaporation, prevents leakage; right volatility and easy to decompose, toxic or high boiling point solvent recovery with excellent effect;

●The equipment is compact, small and light, space saving; removable device, easy operation and installation.

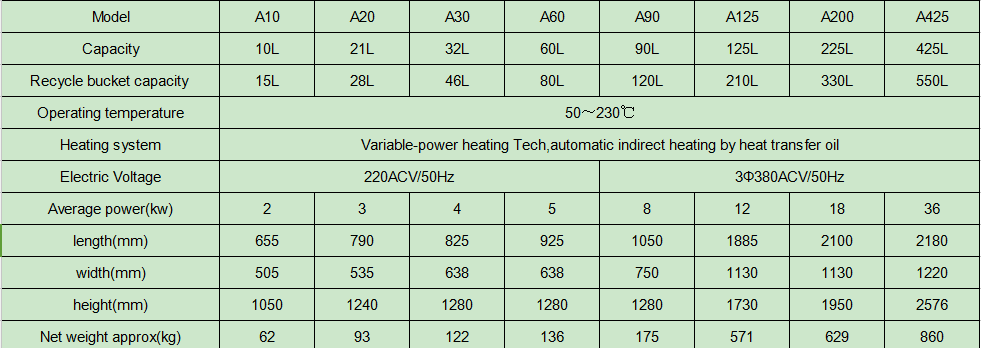

Specifications

(For reference, the data subject to change, please with your choice models the actual date)

| Capacity | Vaccum Pump Swept | Diaphragm Pump | Diaphragm Pump | Dimension | Weight |

| 425/551L | 65/130L/min | 0~61L/min | 200~500L/min | 898X1132X1860 | 96kg |

Product Categories : Auxiliary Devices > Vacuum Pressure Reducing Device

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.