Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

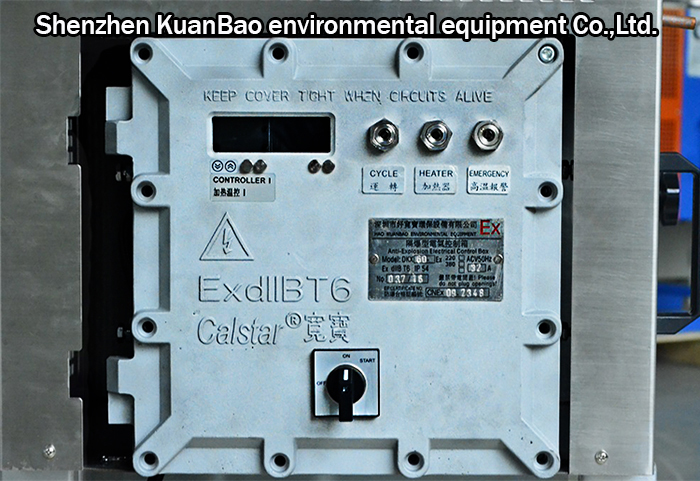

Model No.: A60Ex

Brand: Calstar®

Socket Power: 220ACV/50HZ

Texture Of Material: 304 Stainless Steel

Dimension: 925*638*1280mm

Weight: 136kg

Time Per Cycle: 3Hr

Packaging: Wooden box

Productivity: 500set

Transportation: Ocean

Place of Origin: Shenzhen, China

Supply Ability: 30 sets per day

Certificate: ISO14000,ISO9001,Ex,CE

Port: Shenzhen

Payment Type: L/C,T/T

Incoterm: FOB

solvent recovery machine with Glasses

The Glasses components needs to be thinner to clean.Used after recycling waste thinners can use Solvent Recovery Machine.As long as the access to power, boot operation, look at your savings to soar!

Calstar® Solvent Recycling Equipment models come in 2, 4,6,8,12.5, 12 .5 ,32,50 and 100 Gallon sizes, so we are able to accommodate all sized industries.

No matter what type of solvent you're using, from acetones to thinner, contaminated solvents can be recycled to their original form and become reusable back into your production processes, you can expect to recycle up to 95% of your waste solvent stream.A60Ex has a tilting-type air-cooled condensing system, quality build, and is manufactured according to Chinese explosion-proof directive (CNEX) and European directive (ATEX). The organic solvents are recycled through distillation and cooling.

It is suitable for a medium amount of organic solvent to recycle.

The contaminated solvents will be recycled after a few hours, ready use!

Customer Benefits

· High quality solvent recycling: clear, pure, good performance;

· Low maintenance cost, easy to maintain;

· Easy operation and installation: recycling process and operation are simple. After short-term of training, normal workers are able to operate.

· The equipment is compact, small and light, space saving;

· Short processing time and fast operation time;

· Low investment, quick return on investment.

Characteristic

· Explosion-proof electric equipment: in compliance with Chinese safety directive (CNEX) and European directive (ATEX), worry-free and safe for use;

· In-house developed, standardized production, stable and durable quality assured, good performance;

· Tilting-type: gradually tilt and pour out residue, easy residue removal;

· High quality durable stainless steel tank, prevents chemical corrosion; two-tiered structure, indirect heating, reinforced barrelhead design, precise temperature control, explosion-proof, anti-leakage;

· Heating Method: heating medium (heat transfer oils) indirect heating;

· Digital heating temperature controller: advanced numerical performance, intuitively secure, accurate and convenient heating temperature control;

· Multiple operational safety protection functions:

Pre-set temperature shutdown; Timer shut off; Ultra-high temperature protection;

High-voltage protection; Power failure protection.

Customizing & Auxiliary device:

※You are free to customize the equipment to meet your specific needs, or choose auxiliary device in compliance with your needs in order to achieve the desired treatment effect.

Technical Parameters:

(for reference, the data subject to change, please check with your choice models date).

| Model | Volume | Heating Temperature | Socket Power | Time per Cycle | Dimension | Weight |

| A60Ex | 60L | 50~190°C | 220ACV/50Hz | 3Hr | 925*638*1280mm | 136kg |

NOTE: Values listed above, the recovery time is under ideal conditions in laboratory test values during recovery of toluene for reference.

Application Fields:

Calstar ® solvent recycling machines are suitable in recycling most of common organic solvents used in various industries. The equipment is being widely used in various industries inland and abroad accommodating to wide range of solvent recovery and treatment needs.

1. Automobile manufacturing and repairing industry:

2. Electronic product manufacturing industry (e.g.: LCD, LED, etc.):

Organic solvents for mould cleaning and electronics cleaning, such as: ethanol, acetone, trichloroethylene, etc.

3. Precision instruments and hardware manufacturing industry:

Organic solvents for mould cleaning and products processing, such as: naphtha, hydrocarbons, kerosene, gasoline and other solvents.

4. Sports Equipment Manufacturing:

Detergents for soluble wax casting, such as golf-heads and fishing-rods; solvents for spraying and cleaning golf-sticks and fishing-rods.

5. Footwear industry:

All kinds of organic solvent for spray equipment cleaning, such as equipment for spraying shoe outsoles, heels, processing and cleaning upper print of shoes.

6. Plastic products:

Organic solvents for cleaning and processing, such as: cleaning solvents used in printing.

7. Printing industry:

Detergents for cleaning printing-plates and machines, such as: plate washer solution, car washing solution.

8. Paint Manufacturing Chemical industry:

Organic solvents and paint-mixing solvents for cleaning the production equipment, vessels and bottling equipment, such as: Acetate, ester, chloroform, tri-chloro-ethane, iso-propyl alcohol ethyl ketone (MEK), petroleum solvent, (mineral Oil), naphtha, toluene, xylene, methyl ethyl ketone, n-butyl, mixture organic solvent and so on.

9. FRP products industry:

Solvents, which are used during surface anti-corrosion process and artistic coating process, such as: yacht manufacture, wind turbine blade manufacture.

10. Etching:

Solvents for surface pre-treatment cleaning and electroplating pre-treatment.

11. Optical products:

Solvents, which are used during production of the components, and solvents for pre-treatment of coating.

12. Furniture Manufacturing:

Organic solvents for cleaning spraying equipment and paint-mixing, such as: naphtha, xylene, methyl ethyl ketone, acetone and so on.

13. Other industries that use organic solvents as cleaning agents.

Suitable for these type of solution:

Calstar ® solvent recycling equipment is used to recover organic solvents form liquid solutions, not suitable for recycling gaseous and solid-state materials.It can be widely used in all kinds of cleaning works, where lots of organic solvents are used, such as: Detergents for cleaning spray-guns; trichloro ethylene and toluene solution for cleaning electronics; IPA and anhydrous ethanol for cleaning lens; naphtha in printing industry.Calstar ® machines are suitable for handling and recovering categorized solvents as follows:

Product Categories : Solvent Recovery Machine > Air Cooled Solvent Recovery Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.