Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: A40Ex-VAA

Brand: Calstar

Brand: Calstar

Dimension: 1124*730*1378 Mm

Weight: 165kg

Material Of Tank: 304 Stainless Steel

Power Supply: 220/50ACV/HZ

Cycle Time: 2.5Hr

Type Of Machine: Solvent Recovery

Packaging: Wooden box

Productivity: 500set

Transportation: Ocean

Place of Origin: Shenzhen, China

Supply Ability: 10 sets per day

Certificate: ISO14000,ISO9001,Ex,CE

Port: Shenzhen

Payment Type: L/C,T/T

Incoterm: FOB

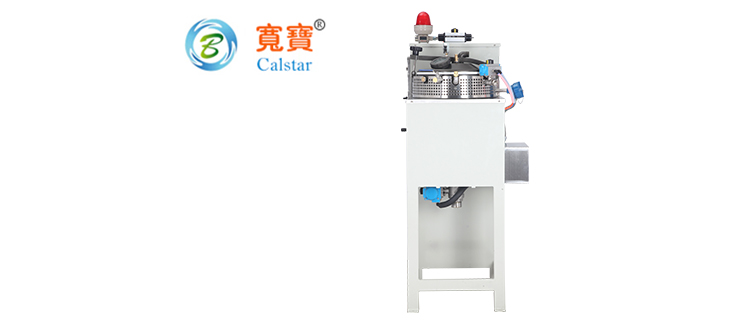

Product Introduction

A40Ex-V, fully automatic recycling machine designed for medium amount of organic solvent recovery. Build-in Automatic input system and Vacuum relief unit for automatic recovery. Tilting-type and air-cooled condensing system, safe structure is manufactured by Chinese explosion-proof standard (CNEX: Ex d IIB T2 Gb, certificate No. CNEx16.2109X) and European standard (ATEX). After distilling and cooling for proximate 2.5 hours, clean organic solvents will be ready for reuse.

It is suitable for medium amount of organic solvent to recycle.

Product Photos

Detailed images

Technical data

Input volume 40 L Length 1124 mm Capacity of Tank 55 L Width 730 mm Capacity of Heat Transfer Oil 21 L Height 1378 mm Power of heater 4.0 KW Weight 165 KG Power of fan 0.09 KW Temp. of operation 50~190 °C Max power 4.2 KW Ideal room temp. 5~30 °C Max current 19.09 A Noise around 65 db. Power supply 220V AC/50 HZ Voltage of control unit 24V DC Heating method Indirect heating by heat transfer oil Cycle time around 2.5 Hours Recovery rate 95% Cooling system Air-cooled Solvent input Automatic input Material of case Carbon steel with paint, or SUS304 Vacuum unit Build-in Vacuum unit Material of tank SUS304, double layers

NOTE: Values listed above are under ideal conditions in laboratory, just for your reference. The realistic data will be a little deviation due to the difference of waste content, boiling point of solvent, room temperature, viscosity etc.

Recoverable solvents list

1. Aromatics categories: toluene, xylene, mesitylene, etc.

2. Aliphatic hydrocarbons: pentane, hexane, octane, etc.

3. Alicyclic hydrocarbons : cyclohexane, cyclohexanone, toluene and cyclohexanone, etc.

4. Halogenated hydrocarbons: chlorobenzene, dichlorobenzene, methylene chloride, trichlorethylene, etc.

5. Alcohols: methanol, ethanol, isopropyl alcohol, etc.

6. Ether: ether, propylene oxide, etc.

7. Esters: methyl acetate, ethyl acetate, butyl acetate, etc.

8. Ketone: acetone, methyl ethyl ketone, methyl isobutyl ketone, etc.

9. As well as other organic solvents that are not listed.

Unrecoverable solvents list

1. Nitrocellulose (nitro), and oxidant solvents and other hazardous materials.

2. Strong acid or strong alkaline solvents.

3. Highly toxic solvents.

4. Pairs of stainless steel or brass with a strong corrosive solvent.

Main Features

● Explosion-proof design: in compliance with Chinese Explosion-proof standards (CNEX) and European standards (ATEX),

● Standardized production, stable and durable quality guaranteed.

● Tilting-type: gradually tilting and pouring out waste residue which is easily removed.

● SUS304 stainless steel tank is used to prevent chemical corrosion. Two layers design, reinforcement barrelhead design, precise temperature control, explosion-proof, anti-leakage are made for safer operation.

● Heating Method: heat medium (heat transfer oils) indirect heating.

● Digital heating temperature controller: advanced numerical display, accurate and convenient heating temperature control.

● Multiple operational safety protection functions: power off or power on by timing or temperature pre-set, excessive temperature protection features; high-voltage protection function; power failure protection function.

● Short reclaiming process, simple operation.

● Less maintenance.

Packing and Delivery

Packing

1. Seaworthy standard wooden box.

Delivery

1. 15 days after payment if equipment in stock, or 30 days after payment if equipment customized.

Certifications

Our clients

Our Service

1. Quick response within 3 hours.

2. Products with international certificate.

3. Products 100% QC checked before shipping.

4. Three-year warranty for completed machine except Heat transfer oil, Gaskets and switches.

5. Customization and Buyer label offered are available.

6. providing professional solution of solvent recovery.

7. providing solvent sample analysis and optimizing solvent formula for free.

8. Wholesale and retail.

9. Pre-sales inquiry and consulting.

10. On site installation and operation training after sales while Volume of machine is 200L equal or above. On the contrary, video of installation and operation training provided.

Product Categories : Solvent Recovery Machine > Full Automatic Solvent Recovery Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.